CYJ series pumping unit

The CYJ series pumping unit is one kind of convention beam pumping unit, is the most common, an application scope broadest surface power equipment in field production oil .

The products conform to API Spec 11E" Specification for Pumping Units", SY/T5044 "Beam Type Pumping unit" and other related standards, and have obtained the certificate of authority to use the official API monogram.

In addition to the production of conventional beam pumping unit, to meet energy-saving requirements of oil company, the company has developed : antiphase beam balanced pumping unit, double horse's head pumping unit, diameter and moment adjusting pumping unit, wheel type pumping unit and so on many kinds of energy saving pumping units.

Technical Features

1. Carry out the design using the modulation and the hypothesized technique of manufacture, optimize the product structure pattern, the spare parts have high level of “the standardization, the universalization, the seriation”.

2. Strength of key parts is calculated with the finite element analysis, the property is stable, the reliability is high.

3.The whole unit operating is simple, the maintenance is convenient, the service life is long.

4. The reducer uses the symmetrical divergence type double circular arc or the involute double helical gear transmission, seal is good, the noise is low, the revolution is steady, it is reliable and durable.

5. The beam uses box beam or I-beam structure, which has high strength, rigidity, large carrying capacity.

6. The horse head is lateral rotary structure, when carrying out the workover, the horse head will rotary 90 °, so that the wellhead is being open position to facilitate operations.

Model | Polished Rod Capacity,Lbs | Stroke Length in Inches | Stroke frequency (r/min) | Balanced type The rated torque | Gear type | Gear ratio |

CYJ3-1.5-6. 5HB | 30 1. | 5 1.2 0. | 9 6 9 12 | Crank balance 6. 5 | DCA/Involute | 30. 25 |

CYJ6-2. 5-26HB | 60 2. | 5 2.1 1. | 7 4 6 8 | Crank balance 26 | DCA/Involute | 34. 357 |

CYJ8-3-37-HB | 80 2. | 5 2.1 1. | 6 4 6 8 | Crank balance 37 | DCA/Involute | 28 |

CYJY8-3-37HB | 80 3 | 2. 5 2. 1 | 4 6 8 | Crank balance 37 | DCA/Involute | 28 |

CYJ8-3-37HFW | 80 3 | 2.5 2.1 | 4 6 8 | Composite balance 37 | DCA/Involute | 28 |

CYJ1O-3-37HB | 100 3 | 2.5 2.1 | 4 6 8 | Crank balance 37 | DCA/Involute | 28 |

CYJY10-3-37HB | 100 3 | 2.5 2.1 | 6 9 12 | Crank balance 37 | DCA/Involute | 28 |

CYJ1O-3-37HFW | 100 3 | 2. 5 2. 1 | 6 9 12 | Composite balance 37 | DCA/Involute | 28 |

CYJ1O-3-53HB | 100 3 | 2.5 2.1 | 6 9 12 | Crank balance 53 | DCA/Involute | 31. 886 |

CYJ1O-3-53HB | 100 3 | 2.5 2.1 | 6 9 12 | Crank balance 53 | DCA/Involute | 31.886 |

CYJ1O-3-53HFW | 100 3 | 2. 5 2. 1 | 6 9 12 | Composite balance 53 | DCA/Involute | 31.886 |

CYJY10-4. 2-53HB | 100 4. | 2 3.6 3 | 6 8 10 | Crank balance 53 | DCA/Involute | 31.886 |

CYJY12-3-53HB | 120 3 | 2.5 2.1 | 6 8 10 | Crank balance 53 | DCA/Involute | 31.886 |

CYJ12-3-53HFW | 120 3 | 2.5 2.1 | 6 8 10 | Composite balance 53 | DCA/Involute | 31.886 |

CYJ12-4. 2-73HFW | 120 4. | 2 3.6 3 | 6 8 10 | Composite balance 73 | DCA/Involute | 31. 73 |

CYJY14-5. 5-73HF | 140 5. | 5 4.6 3. | 7 4 6 8 | Composite balance 73 | DCA/Involute | 31. 73 |

CYJY14-6-73HF | 140 6 | 5 4 | 4 6 8 | Composite balance 73 | DCA/Involute | 31. 73 |

CYJY14-5. 5-89HF | 140 5. | 5 4.6 3. | 7 4 6 8 | Composite balance 89 | DCA/Involute | 39. 69 |

CYJY14-6-89HF | 140 6 | 5 4 | 4 6 8 | Composite balance 89 | DCA/Involute | 39. 69 |

Model | Belt type and specification | power (KW) | speed (r/min) | Structural imbalance | Homework way form | The crank rotation direction | Dimensions |

CYJ3-1.5-6. 5HB | 1X3ZV15J-3810 | 5. 5 | 960 | 1.5 | Hang/Side rotation | Anti-clockwise | 5660X1540X4649 |

CYJ6-2. 5-26HB | 1X4ZV15J-5080 | 22 | 730 | 2 | Hang/Side rotation | Anti-clockwise | 7800X1936X7150 |

CYJ8-3-37-HB | 1X4ZV15J-5380 | 22 | 730 | 2.25 | Hang/Side rotation | Anti-clockwise | 8460X2030X7920 |

CYJY8-3-37HB | 1 X4ZV15J-5380 | 22 | 730 | -0. 5 | Hang/Side rotation | Anti-clockwise | 8460X2030X7916 |

CYJ8-3-37HFW | 1X4ZV15J-5380 | 22 | 730 | 3.8 | Hang/Side rotation | Clockwise | 8460X2030X7916 |

CYJ1O-3-37HB | 1X5ZV15J-5380 | 37 | 740 | 2. 25 | Hang/Side rotation | Clockwise | 8460X2030X7920 |

CYJY1O-3-37HB | 1X5ZV15J-5380 | 37 | 740 | -0. 5 | Hang/Side rotation | Anti-clockwise | 8460X2030X7916 |

CYJ1O-3-37HFW | 1X5ZV15J-5380 | 37 | 740 | 4.5 | Hang/Side rotation | Anti-clockwise | 8460X2030X7916 |

CYJ10-3-53HB | 1X5ZV15J-5380 | 37 | 980 | 2. 25 | Hang/Side rotation | Anti-clockwise | 8460X2140X7916 |

CYJ10-3-53HB | 1X5ZV15J-5380 | 37 | 980 | -0. 5 | Hang/Side rotation | Anti-clockwise | 8460X2140X7916 |

CYJ10-3-53HFW | 1X5ZV15J-5380 | 45 | 980 | 4. 5 | Hang/Side rotation | Anti-clockwise | 8460X2140X7916 |

CYJY10-4. 2-53HB | 1X5ZV15J-6350 | 45 | 980 | 1.59 | Hang/Side rotation | Clockwise | 10760X2196X10102 |

CYJY12-3-53HB | 1X5ZV15J-5880 | 45 | 980 | -0. 5 | Hang/Side rotation | Clockwise | 8660X2140X7916 |

CYJ12-3-53HFW | 1X5ZV15J-5880 | 45 | 980 | 4. 1 | Hang/Side rotation | Clockwise | 8660X2140X7916 |

CYJ12-4. 2-73HFW | 1 X5ZV15J-7100 | 55 | 980 | 3. 8 | Hang/Side rotation | Clockwise | 10760X2690X15152 |

CYJY14-5. 5-73HF | 1X5ZV15J-7100 | 55 | 740 | 1.2 | Hang/Side rotation | Clockwise | 12912X2690X12972 |

CYJY14-6-73HF | 1X5ZV15J-7100 | 55 | 740 | 0. 6 | Hang/Side rotation | Clockwise | 13420X2690X13448 |

CYJY14-5. 5-89HF | 1X5ZV25J-8000 | 55 | 740 | 1.2 | Hang/Side rotation | Clockwise | 12913X2740X12972 |

CYJY14-6-89HF | 1X5ZV25J-8000 | 75 | 740 | 0. 6 | Hang/Side rotation | Clockwise | 13420X2740X13448 |

The API C series pumping unit is one kind of convention beam pumping unit, which selects the crank balanced method. It is the most common, an application scope broadest surface power equipment in field production oil .

The products conform to API Spec 11E " Specification for Pumping Units " and other related standards, and have obtained the certificate of authority to use the official API monogram.

Technical Features

1. Carry out the design using the modulation and the hypothesized technique of manufacture, optimize the product structure pattern, the spare parts have high level of “the standardization, the universalization, the seriation”.

2. Strength of key parts is calculated with the finite element analysis, the property is stable, the reliability is high.

3. The structure is reasonable, work smooth, low noise, the operation maintenance is convenient.

4. In the reducer use the symmetrical divergence type double circular arc or the involute double helical gear transmission, its seal is good, the noise is low, the revolution is steady, it is reliable and durable.

5. The beam is H-beam steel structure, which has high strength, good rigidity, large carrying capacity.

6. The horse head is hanging structure, when carrying out workover, the horse head will be unloaded off .

7. Support is a three-legged structure, convenient in installation, simple operation.

| No | Type | Polished Rod Capacity (lbs) | Stroke Length (in) | Rated Torque (in.lbs) |

| 1 | C-912D-470-240 | 47,000 | 240, 211, 181 | 912,000 |

| 2 | C-912D-427-216 | 42,700 | 216, 185, 155 | 912,000 |

| 3 | C-912D-427-192 | 42,700 | 192, 165, 138 | 912,000 |

| 4 | C-912D-305-192 | 30,500 | 192, 165, 138 | 912,000 |

| 5 | C-912D-365-168 | 36,500 | 168, 144, 121 | 912,000 |

| 6 | C-912D-305-168 | 30,500 | 168, 144, 121 | 912,000 |

| 7 | C-912D-427-144 | 42,700 | 144, 123, 102 | 912,000 |

| 8 | C-640D-305-192 | 30,500 | 192, 165, 138 | 640,000 |

| 9 | C-640D-305-168 | 30,500 | 168, 144, 121 | 640,000 |

| 10 | C-640D-365-144 | 36,500 | 144, 123, 102 | 640,000 |

| 11 | C-640D-305-144 | 30,500 | 144, 123, 102 | 640,000 |

| 12 | C-640D-256-144 | 25,600 | 144, 123, 102 | 640,000 |

| 13 | C-640D-305-120 | 30,500 | 120, 102, 84 | 640,000 |

| 14 | C-456D-305-168 | 30,500 | 168, 144, 121 | 456,000 |

| 15 | C-456D-305-144 | 30,500 | 144, 123, 102 | 456,000 |

| 16 | C-456D-256-144 | 25,600 | 144, 123, 102 | 456,000 |

| 17 | C-456D-365-120 | 36,500 | 120, 102, 84 | 456,000 |

| 18 | C-456D-305-120 | 30,500 | 120, 102, 84 | 456,000 |

| 19 | C-456D-256-120 | 25,600 | 120, 102, 84 | 456,000 |

| 20 | C-320D-256-144 | 25,600 | 144, 123, 102 | 320,000 |

| 21 | C-320D-256-120 | 25,600 | 120, 102, 84 | 320,000 |

| 22 | C-320D-213-120 | 21,300 | 120, 102, 84 | 320,000 |

| 23 | C-320D-305-100 | 30,500 | 100, 85, 70 | 320,000 |

| 24 | C-320D-256-100 | 25,600 | 100, 85, 70 | 320,000 |

| 25 | C-320D-213-86 | 21,300 | 86, 71, 56 | 320,000 |

| 26 | C-228D-213-120 | 21,300 | 120, 102, 84 | 228,000 |

| 27 | C-228D-173-100 | 17,300 | 100, 86, 72 | 228,000 |

| 28 | C-228D-246-86 | 24,600 | 86, 71, 56 | 228,000 |

| 29 | C-228D-213-86 | 21,300 | 86, 71, 56 | 228,000 |

| 30 | C-228D-200-74 | 20,000 | 74, 64, 54 | 228,000 |

| 31 | C-228D-173-74 | 17,300 | 74, 64, 54 | 228,000 |

| 32 | C-160D-173-86 | 17,300 | 86, 74, 62 | 160,000 |

| 33 | C-160D-200-74 | 20,000 | 74, 64, 54 | 160,000 |

| 34 | C-160D-173-74 | 17,300 | 74, 64, 54 | 160,000 |

| 35 | C-160D-143-74 | 14,300 | 74, 64, 54 | 160,000 |

| 36 | C-160D-173-64 | 17,300 | 64, 54, 44 | 160,000 |

| 37 | C-114D-119-86 | 11,900 | 86, 72, 59 | 114,000 |

| 38 | C-114D-143-74 | 14,300 | 74, 62, 51 | 114,000 |

| 39 | C-114D-173-64 | 17,300 | 64, 54, 44 | 114,000 |

| 40 | C-114D-143-64 | 14,300 | 64, 52, 40 | 114,000 |

| 41 | C-114D-133-54 | 13,300 | 54, 45, 36 | 114,000 |

| 42 | C-80D-119-64 | 11,900 | 64, 53, 42 | 80,000 |

| 43 | C-80D-133-54 | 13,300 | 54, 45, 36 | 80,000 |

| 44 | C-80D-119-54 | 11,900 | 54, 45, 36 | 80,000 |

| 45 | C-80D-133-48 | 13,300 | 54, 45, 36 | 80,000 |

| 46 | C-80D-109-48 | 10,900 | 48, 40, 32 | 80,000 |

| 47 | C-57D-76-54 | 7,600 | 54, 41, 28 | 57,000 |

| 48 | C-57D-109-48 | 10,900 | 48, 37, 25 | 57,000 |

| 49 | C-57D-95-48 | 9,500 | 48, 37, 25 | 57,000 |

| 50 | C-57D-89-42 | 8,900 | 42, 33, 23 | 57,000 |

| 51 | C-57D-76-42 | 7,600 | 42, 33, 23 | 57,000 |

| 52 | C-40D-76-48 | 7,600 | 48, 37, 27 | 40,000 |

| 53 | C-40D-89-42 | 8,900 | 42, 33, 23 | 40,000 |

| 54 | C-40D-76-42 | 7,600 | 42, 33, 23 | 40,000 |

| 55 | C-40D-89-36 | 8,900 | 36, 28, 20 | 40,000 |

| 56 | C-25D-67-36 | 6,700 | 36, 28, 20 | 25,000 |

| 57 | C-25D-56-36 | 5,600 | 36, 28, 20 | 25,000 |

| 58 | C-25D-53-30 | 5,300 | 30, 20 | 25,000 |

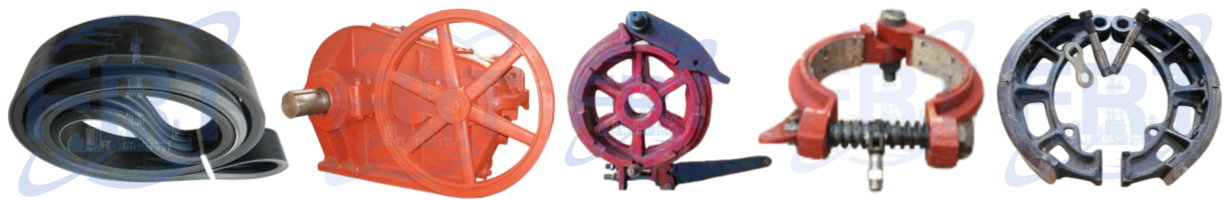

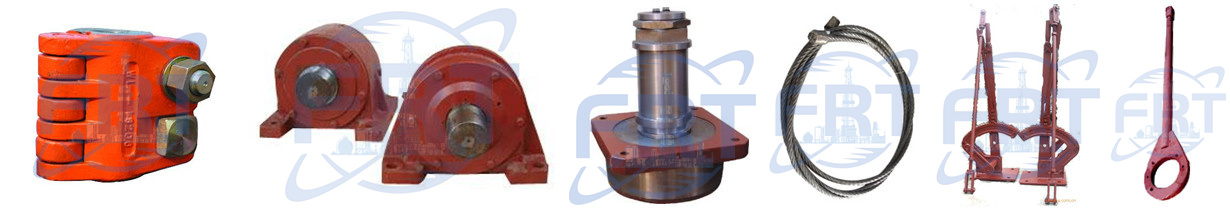

Main spare parts

Field installation

Factory view

Packing&Shipping