The packing element for Annular BOP is a special high performance product for preventing the blowout. The packing element is combined by the main body which is made up of the independent innovation rubber based polymer alloy material and the high strength metal frame, which conforms to the USA 16A, SATM D412, D624, D2240 and D471 standard. It is suitable for the drilling work on the oil field, which shares a high cost performance comparing to the other same type packing elements. And the repair seal kits are equipped.

Physics performance of rubber

| | Technical specification ≤35MPa

| Technical specification ≥70MPa

|

| | | |

| 300% tensile toughness Mpa

| | |

| | | |

| | | |

| | | |

| | | |

| | | |

| Brittleness temperature KN/m

| | |

| Brittleness temperature Mpa

| | |

High performance rubber physics specification (HNBR material, Cameron refer to Cameron type material specification)

| | |

| | |

| 300% tensile toughness Mpa

| |

| | |

| | |

| | |

| | |

| | |

| Brittleness temperature KN/m

| |

| Brittleness temperature Mpa

| |

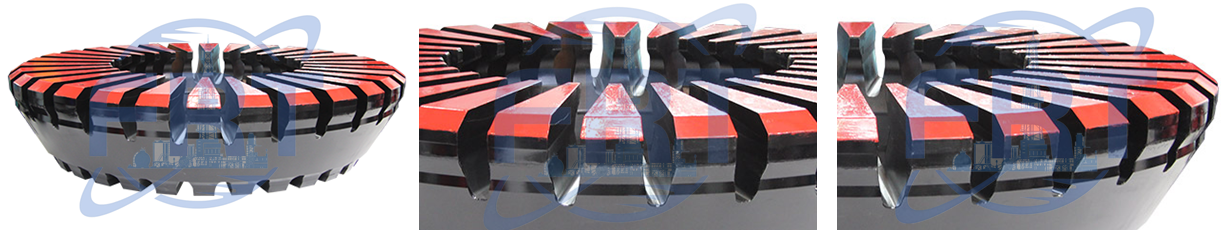

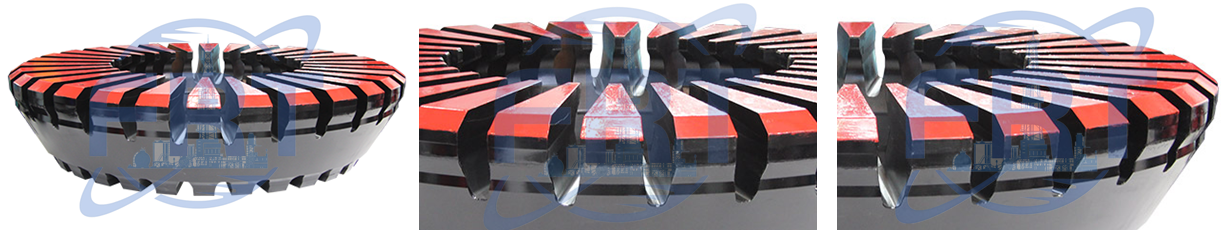

Detailed Images

Spherical Type Packing Element

Taper Type Packing Element

Diverter Packing Element

Size Information

Packing&Shipping

The packing elements will be packed in plywood wooden box.Goods will be delivered by sea, train, truck, air, etc.

Company Introduction

The market share of FRT Machinery is growing steadily and rapidly. Our products have a presence in more than 50 countries and regions in the world, covering North America, Latin America, Russia and Central Asia, the Middle East, Asia Pacific, Europe and Africa. FRT regards continuous learning ability as one of the company's core competitiveness and provides regular training to employees to enhance their comprehensive abilities and skills.

FRT has a skilled and experienced after sales team geared up for fast response and superior services to our customers at any time. Our Long distance monitoring center is equipped to monitor, diagnose, serve and manage the units delivered. FRT also provides technical training to our customers at regular intervals.

1. Can I get samples?

A: Yes, the samples can be provided, but the sample fee and delivery costs need to be paid by your side.

2. Are the packing elements in stock?

A: The common models are in stock, but others need to be produced by orders.

3. Can I have my own Logo on the product?

A: Yes, but the logo need to be sent to us when signing the contract.

4. Can you produce the packing elements according to my own drawings?

A: Yes, we can produce packing elements as per your drawings.

5. Can we visit your company before placing order?

Welcome to our company any time you like.