Type | Desander without downstream drying shale shaker |

Model | WS-2SF / WS-3SF |

Application | For oil gas drilling un-weighted drilling mud |

Features | Small footprint Economic choice No consumable screens |

Result | Wet cuttings, not recommended for Weighted mud and drying solids |

Type | Desander with ZS752 Series Mini Shale Shaker Screen Area:1.4m² |

Application | For oil gas drilling small drilling rig, CBM drilling, HDD, Water Well drilling |

Features | Small footprint Economic choice Acceptable drying solids |

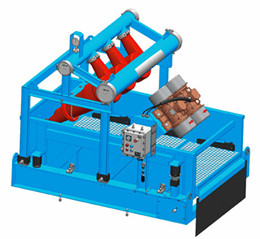

Type | Desander with ZS703 Series 3 Panel Shale Shaker Screen Area:2.6m² |

Model | ZJ703F-S2SF / ZJ703F-S3SF |

Application | For oil gas drilling big drilling rig , large HDD rig, Tunneling Boring Machine etc. |

Features | Big capacity drying solids |

Model | ZJ752F-1S/2S | ZJ703F-S2SF | ZJ703F-S3SF | WS-2SF/3SF | |

Capacity | 120/240 m3/h (528/1056GPM) | 240 m3/h (1056GPM) | 360 m3/h (1584GPM) | 240/360 m3/h (1056/1584GPM) | |

Desander Size(Inch) | 10" | ||||

Desander Qty | 1/2 Pc | 2 Pcs | 3 Pcs | 2/3 Pcs | |

Working Pressure | 0.25~0.4Mpa | ||||

Feeding Size | DN150 | ||||

Output Size | DN200 | ||||

Bottom Shaker Specs. | Shaker Model | ZS752F | ZS703F | N/A | |

Vibration Mode | Linear Motion | ||||

Vibration Motor | 2x0.75Kw | 2x1.72Kw | |||

Screen Qty | 2 Panels | 3 Panels | |||

Screen Size | 750x900mm | 700x1250mm | |||

Screen Area | 1.35m² | 2.63m² | |||

Adjust G Force | ≤7.1G(Adjustable) | ≤7.5G(Adjustable) | |||

Vibration Amplitude | 3.92~5.62mm | 4.14~5.96mm | |||

Deck Angle Range | +2° | -1~+5° | |||

EX Standard | ExdIIBt4/IECEX/A-TEX | ||||

Weight(Kg) | 1059/1114kg | 1835kg | 1924kg | 502/559kg | |

Dimension: mm | 1676x1754x1822 | 2419x2131x1656 | 2419x2135x2066 | 2177x1000x1901 | |

FAQ